Sino

Basic Info.

| Certification | ISO, CE |

| Automation | Automation |

| Production Scope | Product Line |

| After-sales Service | 12 Months |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Food |

| Weight | 1200kg |

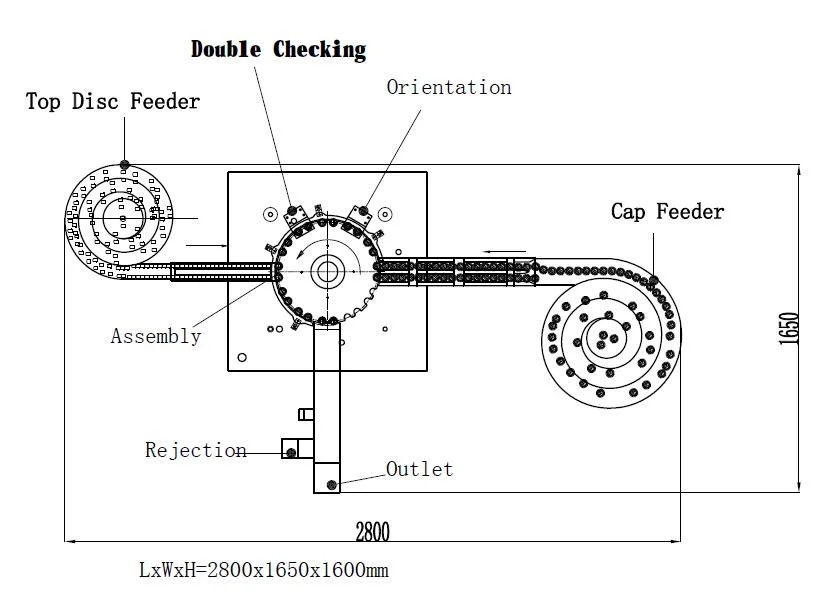

| Dimension(L*W*H) | 2800*1650*1600mm |

| Application | Food, Beverage, Medical, Chemical, Cosmetic |

| Power | 2.5kw+0.5kw |

| Marketing Type | New Product 2023 |

| Condition | New |

| Packaging Type | Export Standard Wooden Cases |

| Key Selling Points | Easy to Operate |

| Driven Type | by Electric |

| Automatic Grade | Automatic |

| Usage | Cap Wadding Inserting Machine |

| Function | Use It to Put The Liner Into The Caps |

| Capacity | 3500-7000caps |

| Production Name | Cap Assembly Machine |

| Transport Package | Iron Tray or Wooden Case |

| Specification | CE, ISO9001 |

| Trademark | SINO-TECH |

| Origin | Made in China |

| HS Code | 8422303090 |

| Production Capacity | 3500-7000caps Per Hour |

Packaging & Delivery

Package Size 280.00cm * 160.00cm * 165.00cm Package Gross Weight 1200.000kgProduct Description

Product Description

Sinotech Full Automatic Plastic Flip Disc Top Lid CapsAssembling Machine

This plastic cap assembly machine is widely adopted by plastic bottle/cap manufacturer, to integrate the separated cover into one cover with various sizes. Widely used in cosmetic, drinks, chemical, medical, food industry etc, which can highly improve productivity and product quality.

Main Features

The machine can produce for different complicated separated and doublets caps combination.

1. Top and bottom cap of hinge cap, completely automatic press fits the assembly.2. Feed in cap material by vibratory disk in order and in correct direction, to ready the caps for main machine and avoid the abrasion outward appearance while process of press fit3. Especially for the products need to meet high requirements on the sanitary condition, it can avoid second-pollution. 4. Automatic Counting device installed, which you can preset the quantity per package,when it reach the quantity, the machine can stop automatic, it can increase your working efficiency and accuracy.5. The PLC Electric control system we use Variable Frequency Control Technology ,which is much more easy operate,stable,widely used, and longer using life.6. This machine meet "GMP"and "CE" standards.

We can provide customized products according to special requirements of customers.

Detailed Photos

01 Automatic Vibrator CapFeeders for top disc and bottom caps sorting and Feeding02 Cap Sensor Detect and Orientation 03 Indexing Assembly 04 Cap Orientation Conveyor05 Top Disc Conveyor 06 Operation Board

Product Parameters

| Productivity Speed | Power | Compress Air | Dimension(L*W*H) | G/Net Weight |

3500-7000caps per hour( according to the cap size) | 2.5 kw+0.5kw | 0.3Kpa/hour-8kg pressure | 2800mm*1650mm*1600mm | 1200KG |

| Main parts Brand | ||

| 1 | Main electronic parts | SIEMENS |

| 2 | Electric protection switch | SIEMENS |

| 3 | Circuit breaker | SIEMENS |

| 4 | PLC | MITSUBISH |

| 5 | Touch screen | WEINVEW |

| 6 | Transducer | MITSUBISH |

| 7 | Photoelectricity switch | AUTONICS |

| 8 | Pneumatic element | AIRTAC |

| 9 | Pressure sensor | SMC |

| 10 | Motor | SIEMENS OR ZHONGDA |

Layout Drawings

Related Products

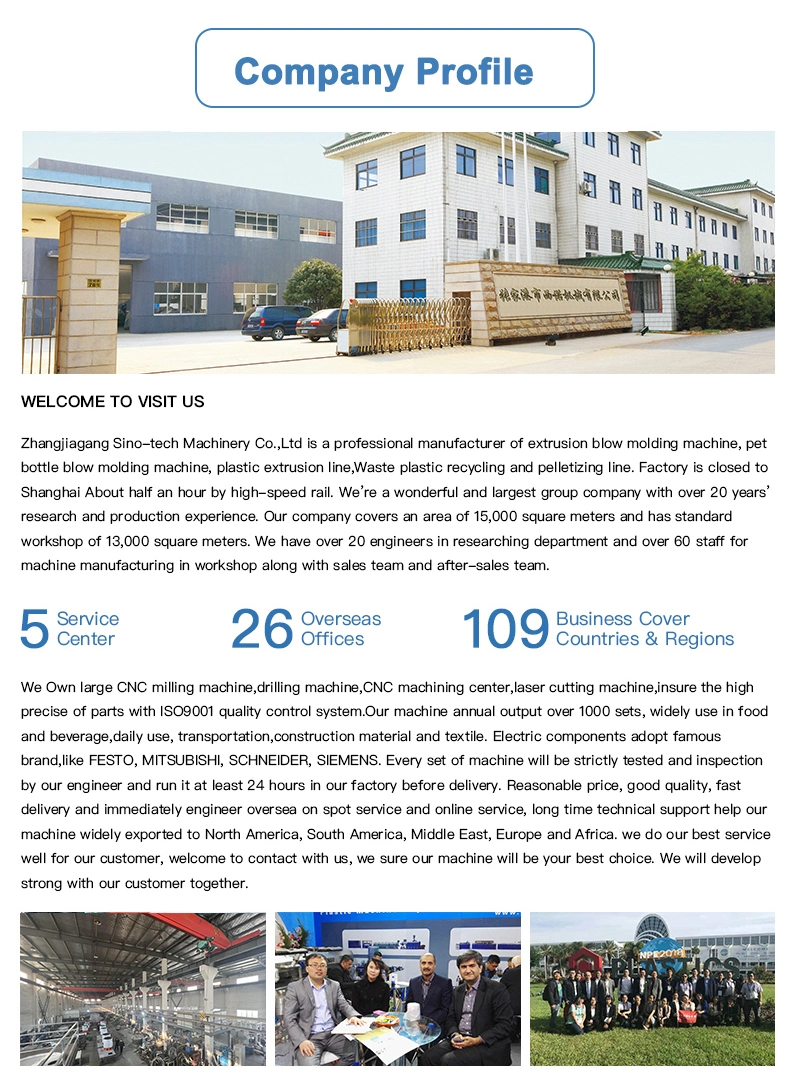

Company Profile

Certifications

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.